100% Biodegradable Recyclable European Packaging standard Brown Printed Carton

Description

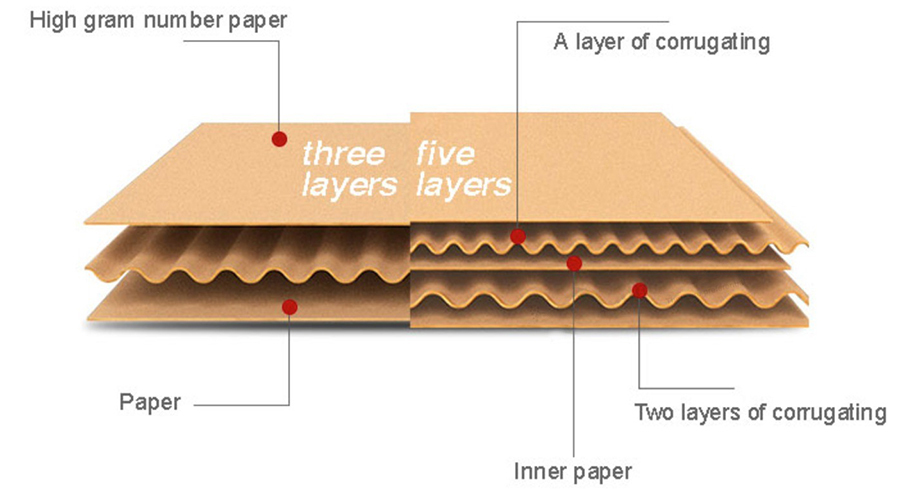

• Lid & Base Box, both use strong corrugated board.

•Top lid with PVC window.

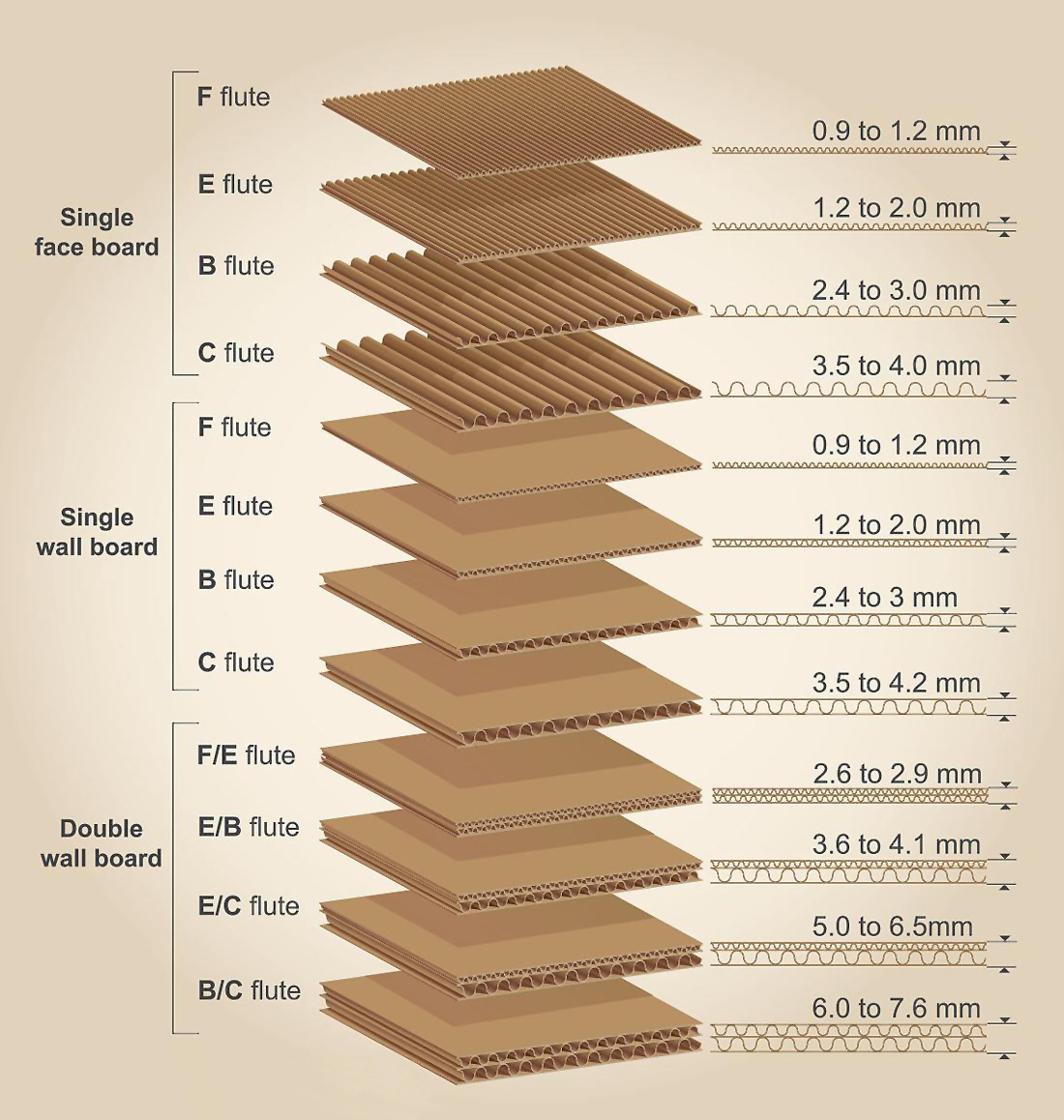

•Using materials: 250 gsm kraft paper/100/100, E flute;

250 gsm kraft paper/120/120, E /B flute;

250 gsm kraft paper/140/140, B flute; To suitable different size and product weight.

100% Biodegradable Recyclable European Packaging standard

Basic Info.

|

Product Name |

Environmental Paper Corrugated Box |

Surface Handling |

No lamination |

|

Box Style |

Cover & Tray Carton |

Logo Printing |

OEM |

|

Material Structure |

Kraft paper + Corrugated Paper + Brown Paper |

Origin |

Ningbo,Shanghai port |

|

Weight |

250gram kraft/120/120, E flute |

Sample |

Accept |

|

Rectangle |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 working days based on quantity |

|

Printing |

White UV Printing |

Transport Package |

By carton, bundle,pallets |

|

Type |

Single Printing on kraft paper |

Shipping |

By sea, air, express |

Detailed Images

Packaging structure design can also play a decisive role in the sale of goods. An excellent packaging structure not only better display goods,but also bring convenience to consumers.

Material Structure and Application

♦ Corrugated board

Corrugated board like a connected arch door, side by side into a row, mutual support, forming a triangular structure, with good mechanical strength, from the plane can also withstand a certain pressure, and is flexible, good buffering effect; It can be made into various shapes and sizes of pads or containers according to need, which is simpler and faster than plastic cushioning materials; It is not affected by temperature, good shading, no deterioration by light, and generally less affected by humidity, but it is not suitable for long-term use in the environment with high humidity, which will affect its strength.color.

♦ Corrugated Paperboard

♦ Packaging Applications

Corrugated boxes are made of corrugated cardboard, is the most widely used paper container packaging, widely used in transportation packaging.

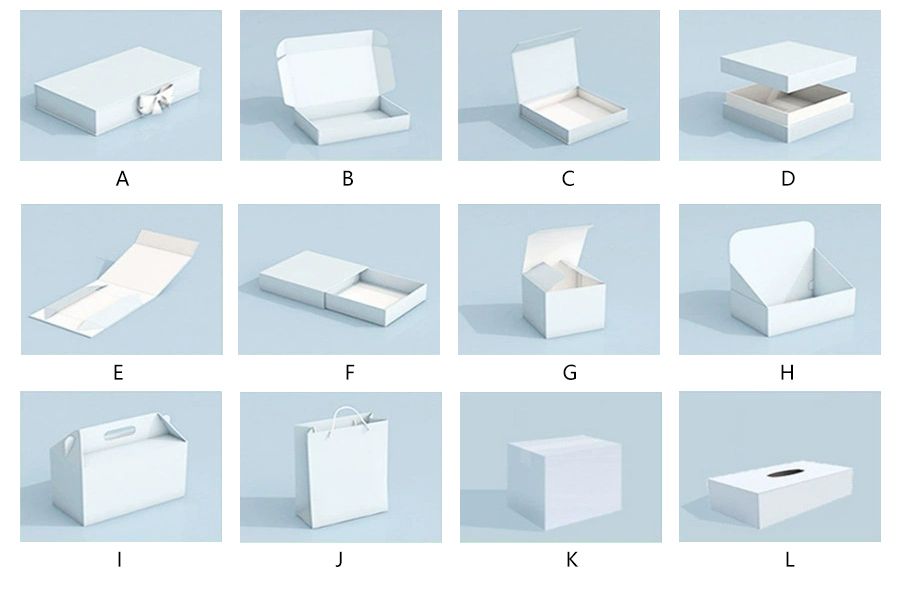

Box Type and Finish Surface

♦ Box Designs

Carton structure can be customized according to customer requirements. Common structures are: cover type structure, shake type structure, window type structure, drawer type structure, carrying type structure, display type structure, closed structure, heterogeneous structure and so on.

♦ UV printing

• UV printing is a printing process in which ink is dried and cured by ultraviolet light. It is necessary to combine the ink containing photosensitizer with the UV curable lamp.

• The application of UV printing is one of the most important content in the printing industry. UV ink has covered offset printing, screen, inkjet, pad printing and other fields, the traditional printing industry refers to the

• UV printing effect process, is in a print you want the pattern above wrapped in a layer of glossy oil (bright, matte, inlaid crystal, gold scallion powder, etc.), mainly to increase the product brightness and artistic effect, protect the product surface, its hardness is high, Corrosion resistance friction, not easy to appear scratches, etc., some coating products are now changed to UV, can meet the requirements of environmental protection, but UV products are not easy to stick, some can only be solved by local UV or grinding.