China Factory sturdy printing recycled kraft paper packaging box

Description

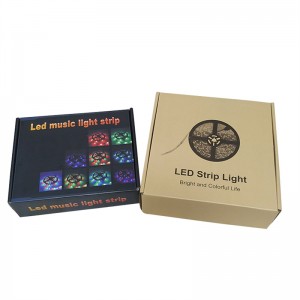

This is a brown corrugated product box, the bottom is self lock style. It’s offset printing used for this box, if there is white color in your design, and you required high quality about it, then UV printing is better.

Basic Info.

| Product Name | Brown Corrugated Product Box | Surface Treatment | No need. |

| Box Style | Product box | Logo Printing | Customized Logo |

| Material Structure | 3 layers, corrugated board. | Origin | Ningbo city, China |

| Weight | 32ECT, 44ECT, etc. | Sample type | Printing sample, or no print. |

| Shape | Rectangle | Sample Lead Time | 2-5 working days |

| Color | CMYK, Pantone color. | Production Lead Time | 12-15 natural days |

| Printing mode | Offset Printing | Transport Package | Standard export carton |

| Type | Single-sided Printing Box | MOQ | 2,000PCS |

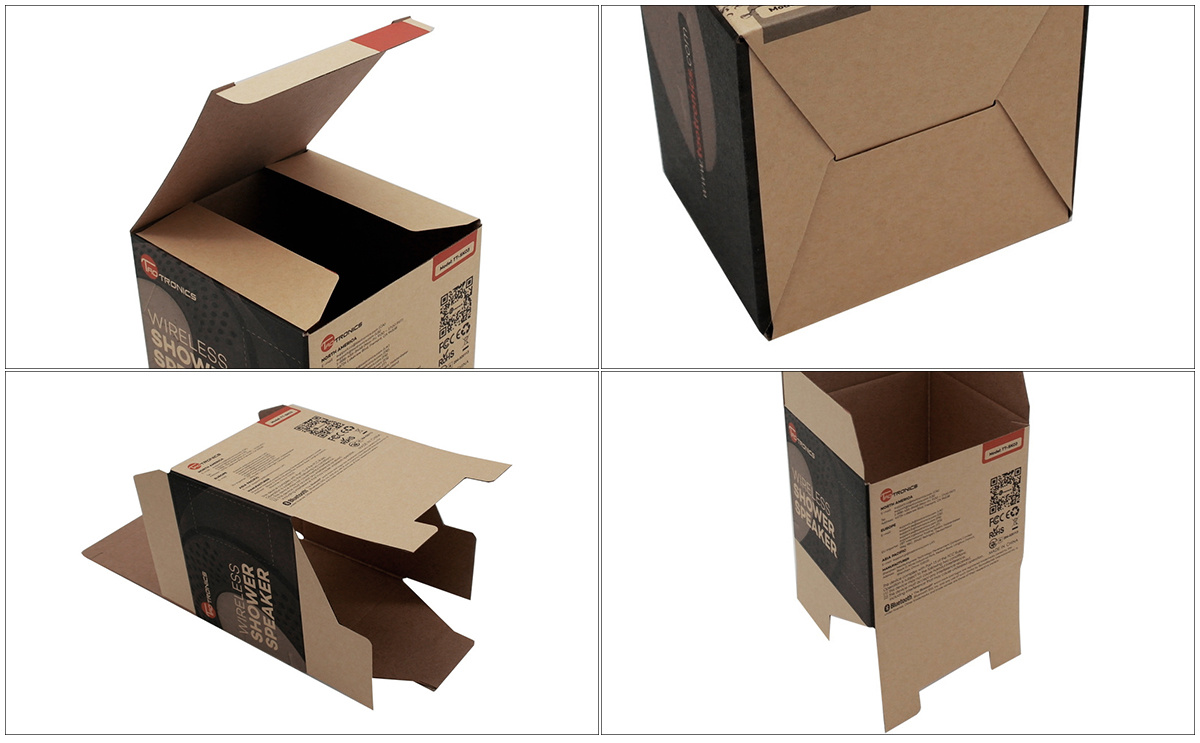

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

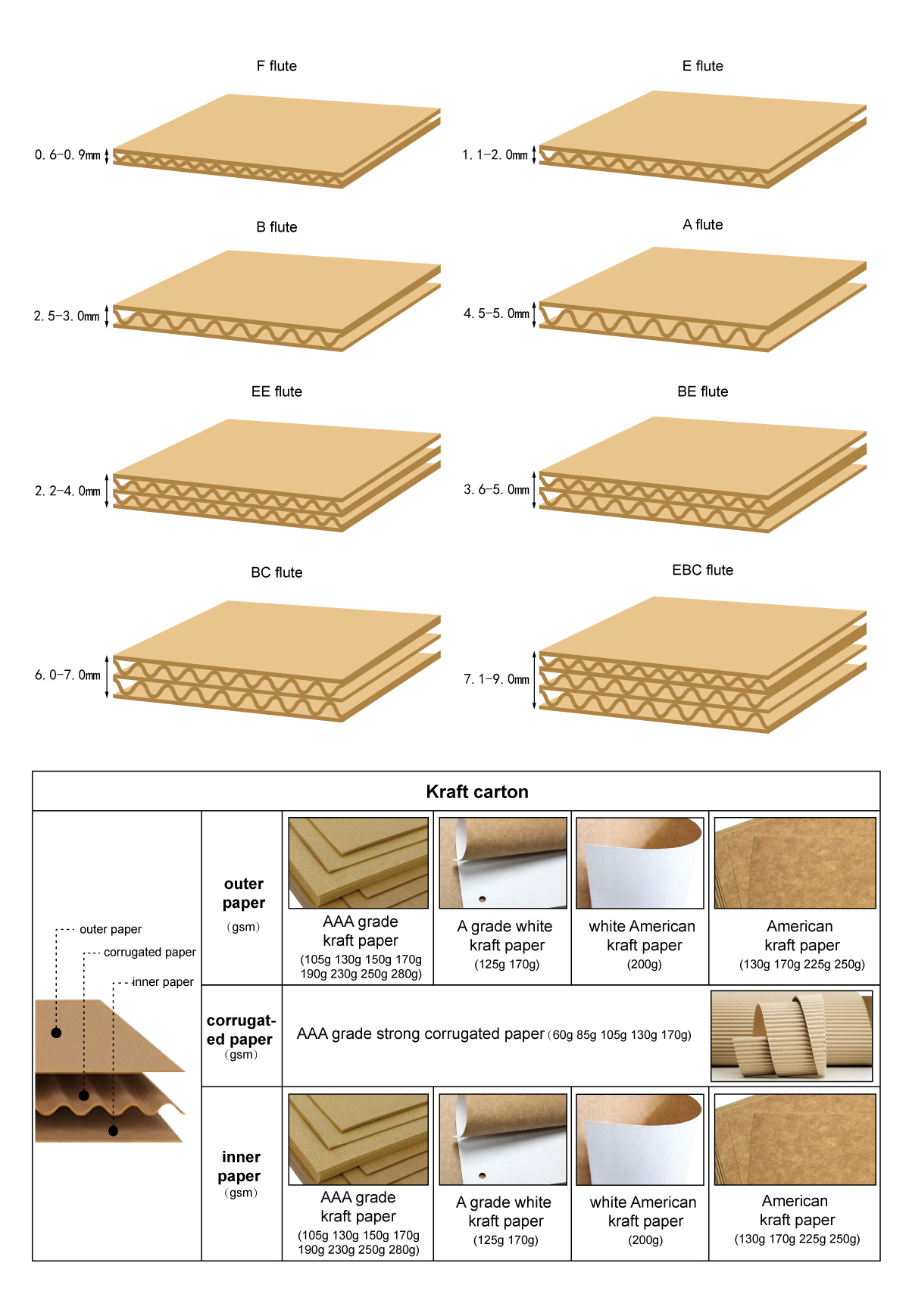

Material Structure and Application

Corrugated paperboard can be divided into 3 layers, 5 layers and 7 layers according to the combined structure.

The thicker “A Flute” corrugated box has better compressive strength than “B Flute” and “C Flute”.

“B Flute” corrugated box are suitable for packing heavy and hard goods, and are mostly used for packing canned and bottled goods. “C Flute” performance is close to “A Flute”. “E Flute” has the highest compression resistance, but its shock absorption capacity is slightly poor.

Corrugated Paperboard Structure Diagram

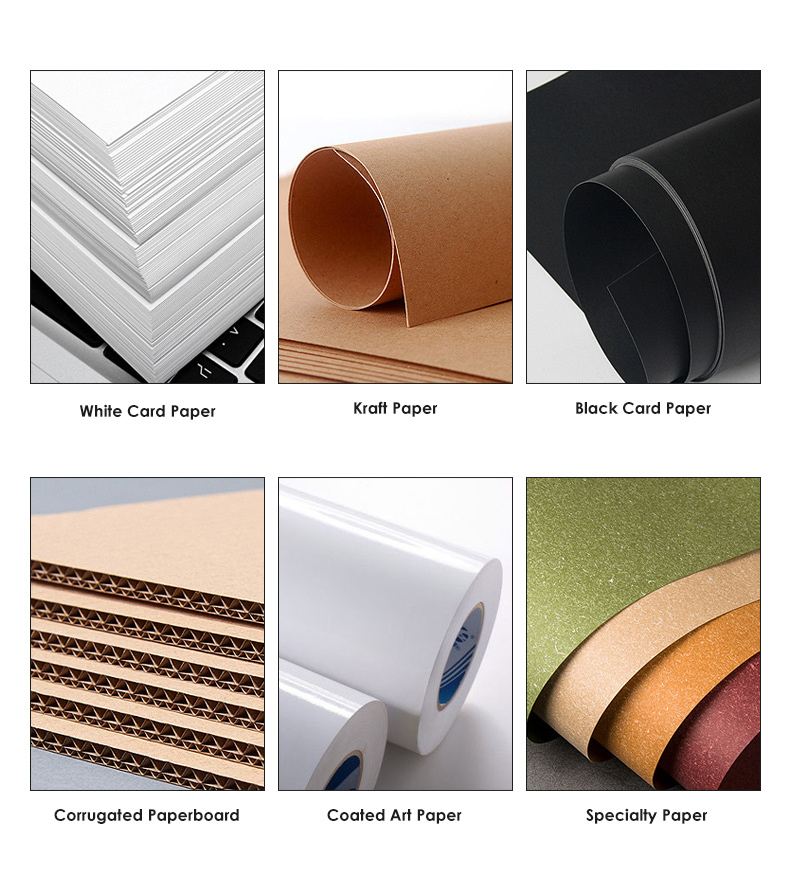

Box Type and Finish Surface

Paper Type

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.