White OEM Design Printing Corrugated Carton Package Mailer Box for Express Delivery

Description

Corrugated board first began in the late 18th century. In the 19th century, people found that corrugated board is not only light, strong performance, the price is cheaper than the general material, and the production process is simple, more widely used. Moreover, corrugated cardboard is not only a recyclable and environmentally friendly material composed of wood fibers that can be decomposed by natural action, but also can be reused without affecting its performance.

• Applications:

Firm small medium size express carton box;

Made of environmentally friendly materials.

• Gram of each layer:

250 gram white greyboard/100/120 white kraft paper, E flute;

• Printing technology & Surface disposal

Outer offset printing in CMYK with Matt lamination.

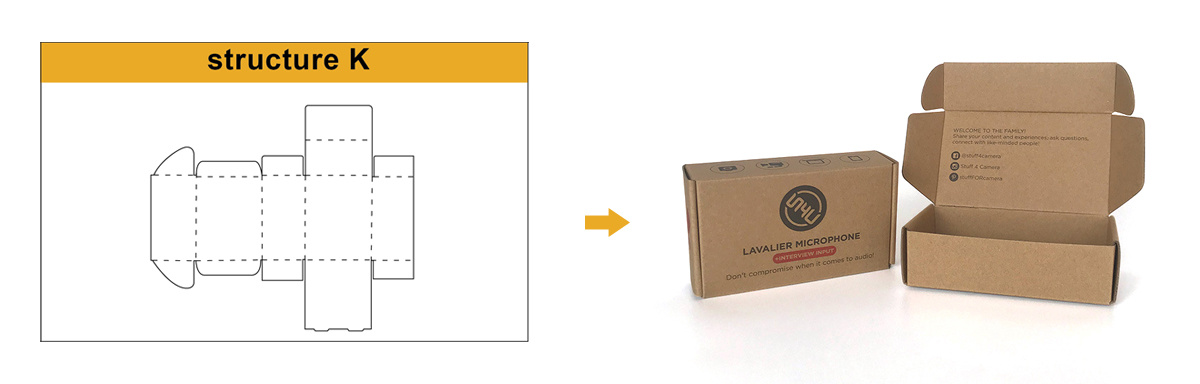

• Structural representation

Basic Info.

|

Product Name |

White Corrugated Mailer Box |

Surface Handling |

Matt Lamination |

|

Box Style |

Structure K |

Logo Printing |

OEM |

|

Material Structure |

White Board + Corrugated Paper + White Board/kraft paper |

Origin |

Ningbo, Shanghai port; |

|

Weight |

190gram weight |

Sample |

Accept |

|

Rectangle |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Shipping |

Sea freight, air freight, Express |

|

Printing |

Offset Printing |

Transport Package |

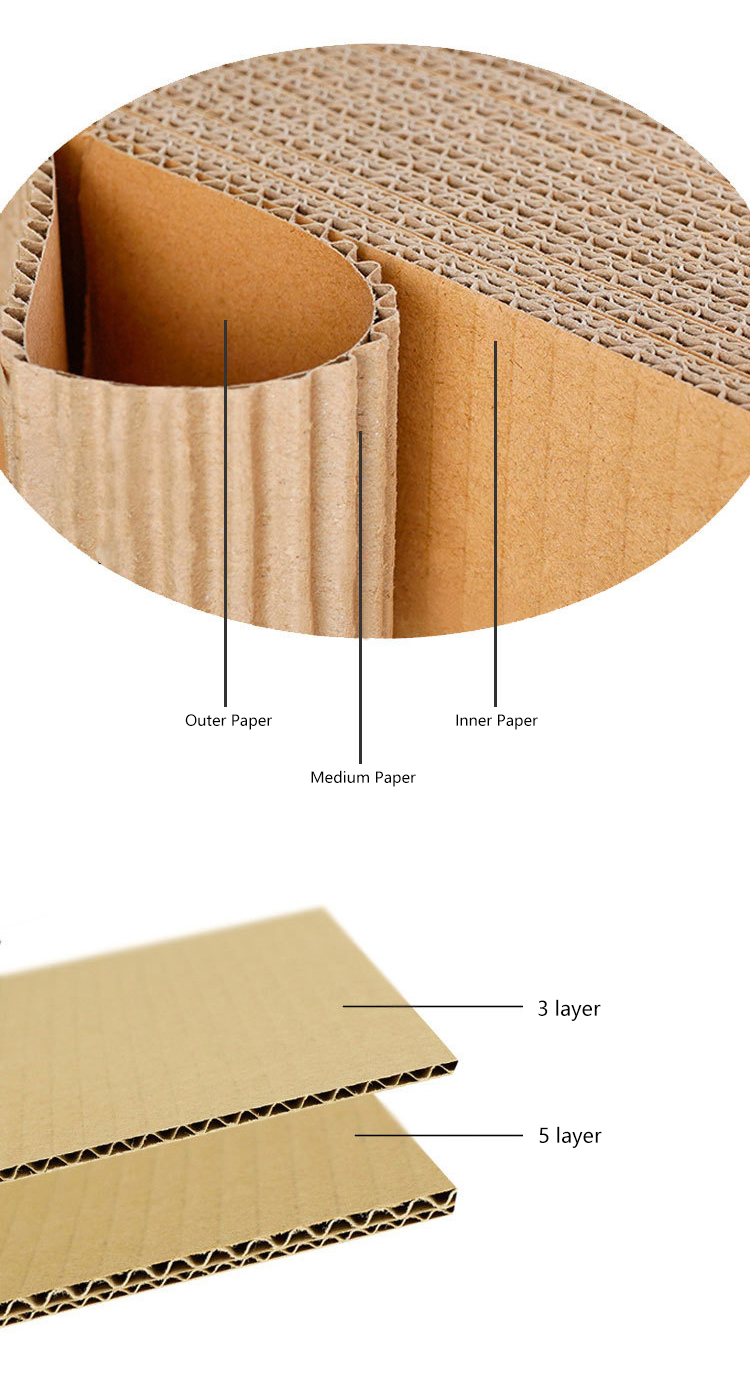

Strong 3 ply/5 ply Corrugated Carton |

|

Type |

Single /Two-sided Printing Box |

Business term |

FOB, CIF, etc. |

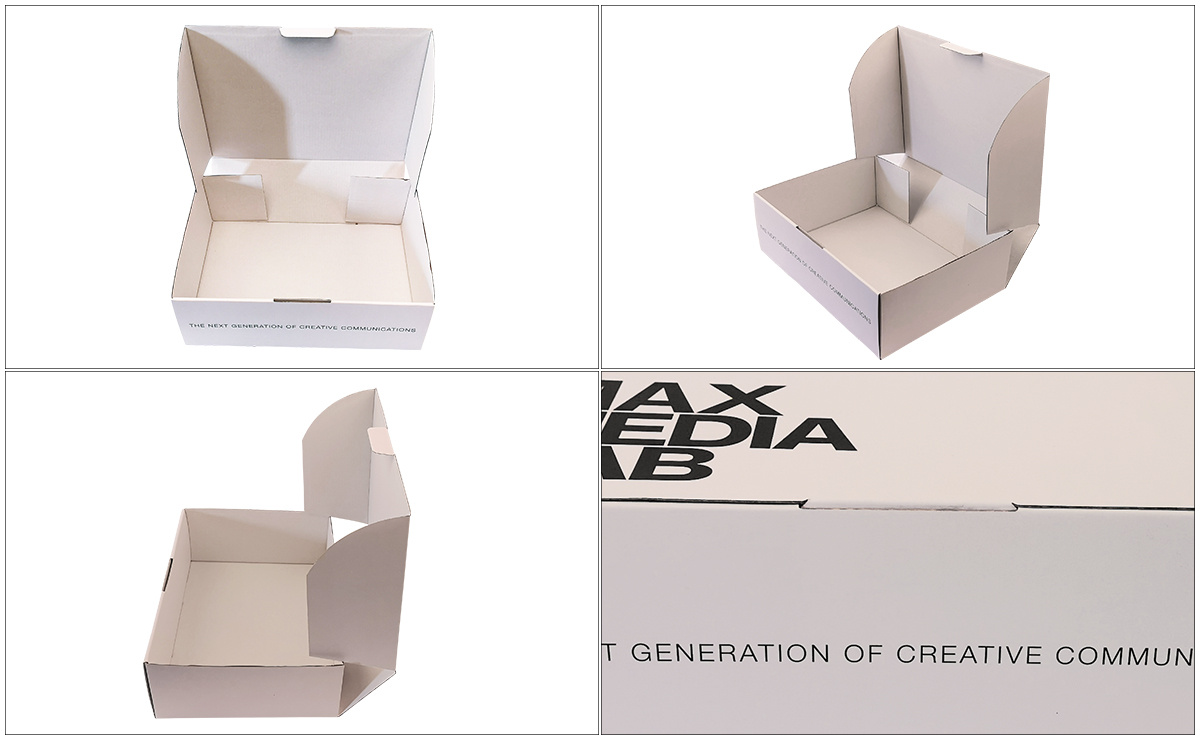

Detailed Images

At the beginning of the 20th century, because the packaging container made of corrugated cardboard has its unique performance and advantages to beautify and protect the inner goods, corrugated cardboard began to be comprehensively grade, promotion and application, has become a variety of products in different fields of protective packaging outerwear, in the competition with a variety of packaging materials has achieved unprecedented great success. In the nearly two centuries like flooding expansion development and huge market coverage, corrugated cardboard in a real sense has become so far long used and still showing rapid development of the production of packaging container one of the main materials.

• 3 Constituent material

Surface paper: One side white coated paper;

Corrugated: E flute;

Inside paper: white kraft paper.

• Printing machine

4 Color printing machine

Material Structure and Application

• Corrugated Board

Corrugated corrugated board like a connected arch door, side by side into a row, mutual support, forming a triangular structure, with good mechanical strength, from the plane can also withstand a certain pressure, and is flexible, good buffering effect; It can be made into various shapes and sizes of pads or containers according to need, which is simpler and faster than plastic cushioning materials; It is not affected by temperature, good shading, no deterioration by light, and generally less affected by humidity, but it is not suitable for long-term use in the environment with high humidity, which will affect its strength.

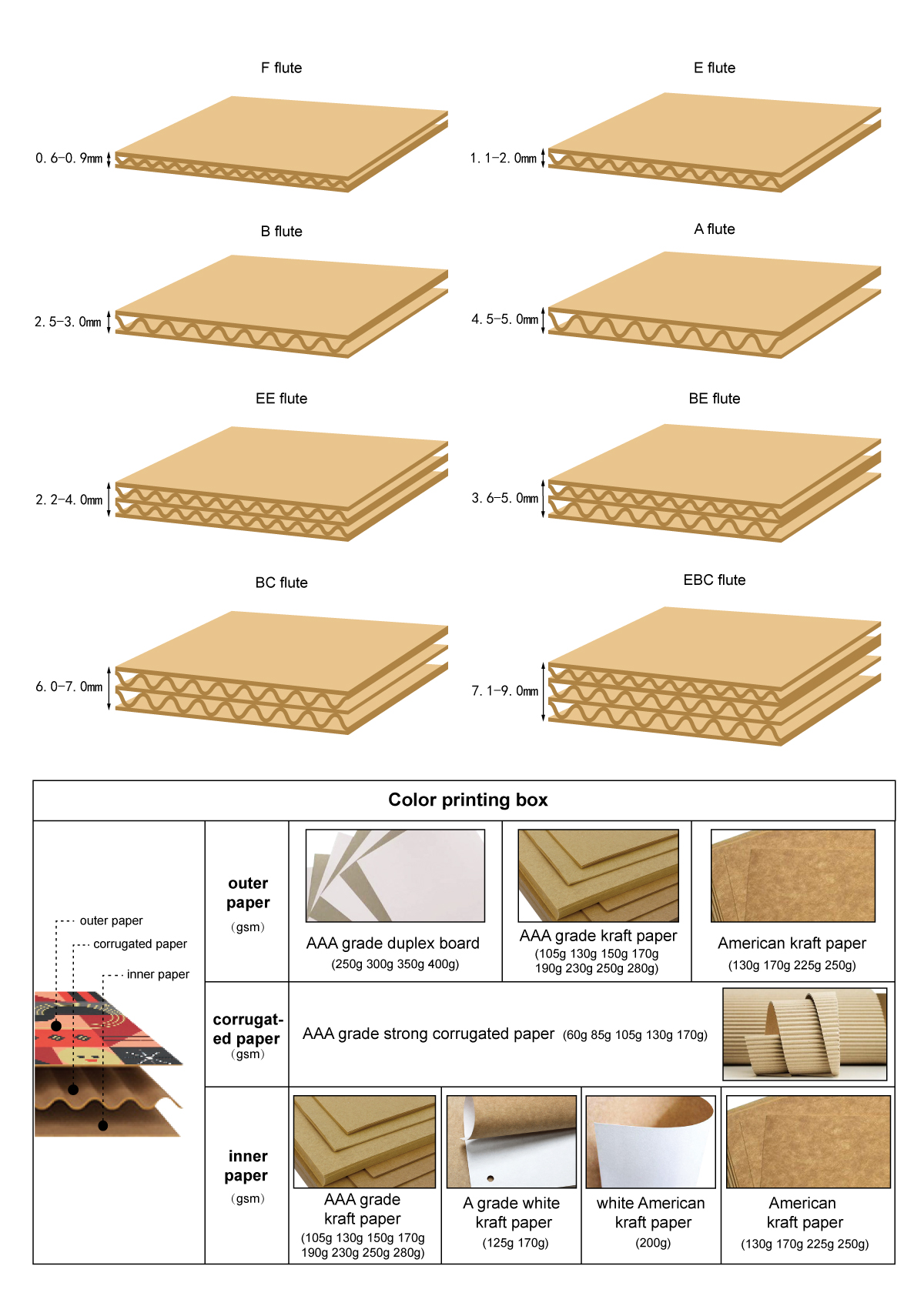

• Corrugated Paperboard Structure Diagram

Corrugated paper is made of hanging paper and corrugated paper formed by corrugated roller processing and bonding board.

generally divided into single corrugated board and double corrugated board two categories, according to the size of corrugated is divided into: A, B, C, E, F five types.

• Packaging Applications

Corrugated cardboard began in the late 18th century, the early 19th century because of its light weight and cheap, wide use, easy to make, and can be recycled or even reused, so that its application has a significant growth. By the beginning of the 20th century, it had been widely used to make packaging for a wide variety of commodities. Because the packaging container made of corrugated cardboard has its unique performance and advantages to beautify and protect the goods inside, so it has achieved great success in the competition with a variety of packaging materials. So far, it has become one of the main materials for making packaging containers, which has been used for a long time and presented rapid development.

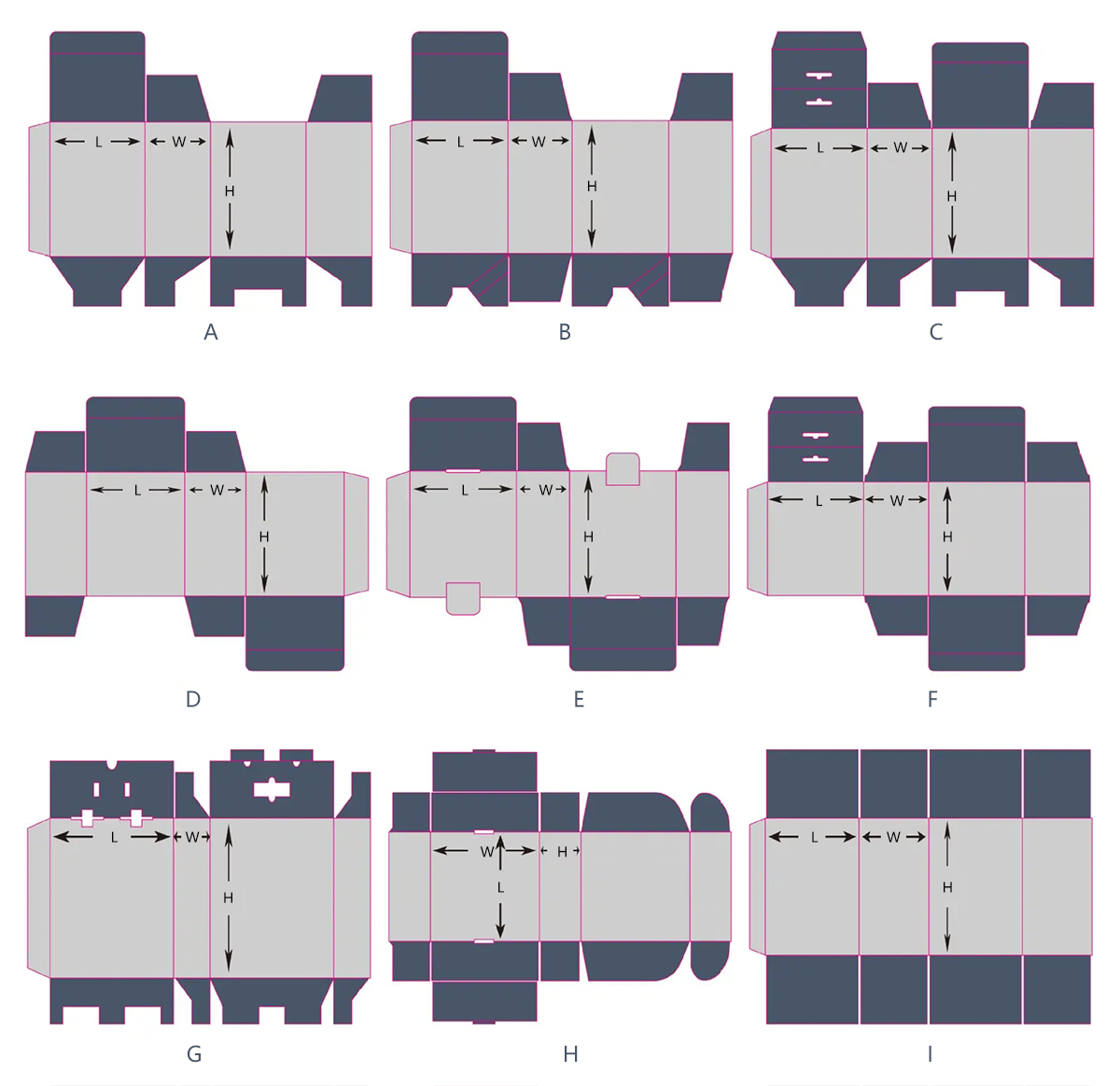

Box Type and Finish Surface

♦ Box Type

Packaging structure design can also play a decisive role in the sale of goods. An excellent packaging structure not only better display goods,but also bring convenience to consumers.

♦ Structure kinds

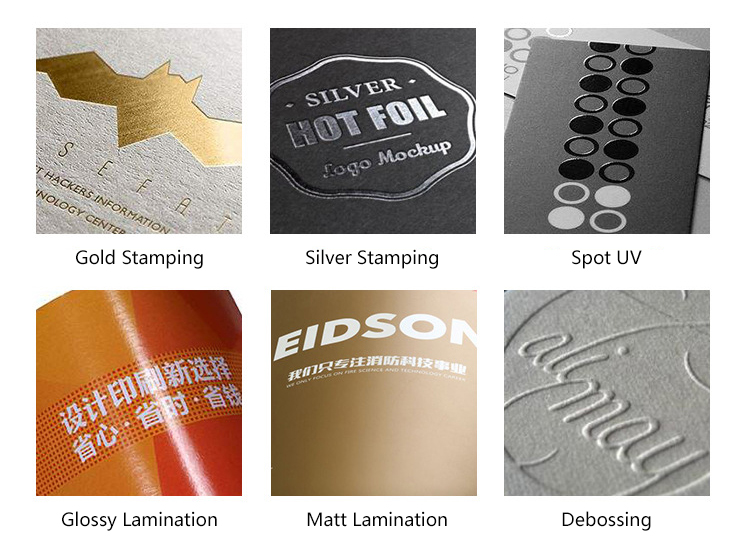

♦ Common Surface Treatment

Protect the color of the carton surface. The color image is the most direct message delivered by the gift box. If the color is removed, faded and faded, it is easy to leave the impression of poor quality and cheap. With oil and pvc lamination can protect the color of the surface of the carton, and the print will not fade easily under the ultraviolet light.

♦ Matt Lamination & Glossy Lamination

Laminating is the plastic film coated with adhesive, and the paper as substrate printed matter, after the rubber roller and heating roller pressure together, forming a paper-plastic product. Covered with matte film, is in the name card surface covered with a layer of frosted texture film; Coating film, is a layer of glossy film on the surface of the business card. The coated products, due to its surface more than a layer of thin and transparent plastic film, smooth and bright surface, graphic color more bright, at the same time play the role of waterproof, anti-corrosion, wear resistance, dirty resistance and so on.